Duroplast toilet seat cover, wrapped design makes the toilet lid look more mature and stable.

Brand:

SuntenItem NO.:

SU015Payment:

T/T, L/C, Paypal , Western UnionProduct Origin:

Xiamen, Fujian, ChinaColor:

White or OEM other colorShipping Port:

XiamenLead Time:

23-30 daysOrder(MOQ):

200 setsProduct weight:

2.4 KGProduct Detail

Duroplast toilet seat cover, wrapped design makes the toilet lid look more mature and stable.

| Item: | SU015 |

|

| Shape: | D-shape | |

| Type: | Wrap over toilet seat | |

| Hinge spacing: | 135-175 mm | |

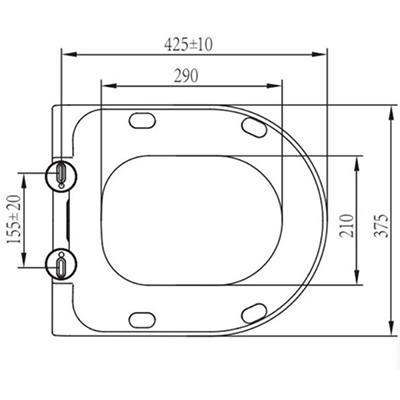

| Size: | 425*375 mm | |

| Certification: | BSCI, ISO, REACH, TUV, DIN | |

| Sample: | 3-5 days | |

| Delivery: | 25-30 days | |

| Color: | White or customized color as your need | |

| Hinges: | Top fixing or bottom fixing | |

|

Mention: welcome to contact us to get more product details |

||

|

Slowly Close, comfortable and Silent The slow-close design enables the toilet lid to be opened and closed while achieving a silent effect, reducing friction and collision, and improving the service life of the toilet lid. |

|

Antibacterial Material Containing more than 90% of antibacterial agents, the smooth surface can also reduce the residual bacteria. |

|

|

Anti-scratch Sharp objects are not easy to scratch the surface of the product and have good scratch resistance properties. |

|

Durable The toilet seat is compressed by urea-formaldehyde material at high temperature, with good compressive capacity and can withstand 300kg. |

|

SU015 is the classic wrap over D shape standard toilet seat, its designed concept comes from the V&B subway series, it has the common European toilet seat cover size, it can fit most of the D shaped bowl.

First Step

the toilet seat needs the molding process, we use the best urea material, 100% new material let the toilet seat has very perfect performance. The worker weigh the material and then dry it when the mold temperature is eligible, they put the dried material into the mold, after the molding processing, they take off the toilet seat, cut the flashes, adjust the shape and do the initial check.

Second Step

polishing processing, the professional worker checks each detail and does the polishing. They check each lid and ring, they find the flaws and judge it. If the flaw can't be fixed, they scrap it. If the flaws are on the superficiality, they fixed the flaws carefully.

Finally

inspection, each toilet seat will be inspected and then do cleaning and assembly, after assembly, we did function test for each toilet seat and then do the package.

After the strict production control, the toilet seat is in good quality and has a very good performance and longer lifetime. Looking forward to your inquiry about European standard bathroom wrap over d shape toilet seat cover.

APPLICATION

Opportunity meets the prepared mind, as the old saying goes.![]()